Slab Leaks: What Causes Them and How To Repair Them

Slab leaks are a fact of life in areas where soils are unstable. Homes are built on concrete slabs or using pier and beam construction because basement walls can crack and break from the pressure of shifting soils.

Slab construction became popular during the post-WWII construction boom because it was faster and cheaper. A rebar-reinforced 4” – 6” thick concrete slab is poured directly on a prepared surface. Plumbing lines are run beneath the slab, where they are difficult to reach.

Sometimes the plumbing joints leak or the pipes crack beneath a slab, and then you have one of the most serious problems you could imagine – a slab leak.

As water runs under the house it erodes the soil. This removes support for the slab and puts more strain on it and may cause it to develop cracks from hairline width to an inch or more. Then all that water has a clear path into your house.

Depending on the extent of the leak, you may experience serious water damage to flooring, walls, furniture, appliances, and more. And, as you can imagine, fixing a leak beneath tons of concrete is no walk in the park, and it’s definitely not a DIY plumbing job.

Plumbing Materials Can Cause Slab Leaks

Slab leaks result from some type of failure in a home’s plumbing system. The failure could be caused by faulty installation, weakened water lines, chemical reactions of metals in the earth to metals in the plumbing system, or – drum roll – soil shifting beneath the slab.

We’ll come back to that last one in a minute. First, let’s consider the materials the pipes are made of, which often is a function of the age of the plumbing system. The materials themselves sometimes are the problem. Unless you were able to see the original plumbing work during construction you will have little idea of where the lines run, what they’re made of, and how good the installation work was.

Cast iron pipe was the staple for most homes built prior to the 1960s, although plastics have become more popular since. Cast iron plumbing lines above ground in a house does offer some advantages. Cast iron is quieter than plastic because it vibrates less, so you don’t hear water running through the lines as readily. It is very durable and will not burn – which can be important in case of fire.

Cast iron pipe was the staple for most homes built prior to the 1960s, although plastics have become more popular since. Cast iron plumbing lines above ground in a house does offer some advantages. Cast iron is quieter than plastic because it vibrates less, so you don’t hear water running through the lines as readily. It is very durable and will not burn – which can be important in case of fire.

But unprotected cast iron installed as underground service lines can be corroded by water and minerals in the soil. To address that, some cast iron pipes made today are sheathed in a protective material. These are far superior to the old pipes commonly used into the 1960s.

Galvanized steel pipes also were common in homes through the 1950s. Like cast iron, galvanized steel is strong, but susceptible to corrosion. Galvanized pipe also is more prone to clogging. The coating inside the pipes eventually wears off, leaving the pipes vulnerable to rust and mineral buildup that can clog the lines solid with minerals and waste matter. The useful life of galvanized steel plumbing pipe is about 50 years.

Rigid copper pipe remains a popular choice today, especially for hot and cold water supply lines. Flexible copper pipe is used for water supply lines to appliances such as refrigerator icemakers and dishwashers. Copper is durable and corrosion-resistant. Copper pipe comes in different wall thicknesses. Underground lines should be run using copper pipe with the thickest walls. Even then, careful installation is called for. A dent in a water line can eventually wear thin from the constant flow of water and eventually open a small hole in the pipe.

Plastic pipes are corrosion-resistant and can be used above or below the ground. Plastic resists corrosion and is relatively easy to work with. Most common types include:

- ABS (acrylonitrile butadiene styrene) – black in color, ABS was the first plastic pipe used in residential plumbing. There have been problems keeping ABS joints together, which has led some municipalities to disallow it in new construction. A failed joint beneath a slab will result in a costly slab leak. Also, ABS can deform when exposed to direct sunlight, so it’s not suitable for all above-ground installations.

PVC (polyvinyl chloride pipe) – the more commonly used plastic plumbing pipe now. Colors indicate intended usage, including white for drain lines and irrigation, blue for potable water, green for sewer water, purple for reclaimed water, gray for electrical conduit.

PVC (polyvinyl chloride pipe) – the more commonly used plastic plumbing pipe now. Colors indicate intended usage, including white for drain lines and irrigation, blue for potable water, green for sewer water, purple for reclaimed water, gray for electrical conduit.- CPVC (chlorinated polyvinyl chloride pipe – similar to PVC, but the chlorination process gives CPVC different physical properties. CPVC’s ability to withstand higher temperatures makes it more suitable than PVC for hot water lines.

- PEX (cross-linked polyethylene) – the newest plastic plumbing pipe, PEX is used as an alternative to PVC, CPVC, and copper. It is flexible, cuts easily, and uses compression fittings, which makes PEX relatively simple to install. It also has some drawbacks. Making secure connections requires some skill, and its flexibility can cause vibration and movement problems. If not carefully secured PEX can be abraded by movement over structures such as floor joists and rafters.

Expansive Soil Shift Is the #1 Cause of Slab Leaks

While the materials used and how they are installed in under-the-slab plumbing can result in slab leaks, by far the biggest cause is the shifting of expansive soils that homes are built on. The American Society of Civil Engineers says about 25% of all homes in the United States experience damage due to expansive soils. In fact, the ASCE estimated the total cost of damage caused by expansive soils is around $2.3 billion per year in the US alone. According to geology.com, that is more than the cost of property damage caused by floods, earthquakes, hurricanes, and tornadoes combined!

A slow slab leak keeps putting water into the ground beneath a home, which creates even more soil expansion that ultimately can lead to substantial damage. The buildup of hydraulic pressure beneath a slab will be released somewhere. Upward pressure eventually finds its way to any weakness or crack in the slab. In some cases, wet spots develop in hardwood floors and carpeting; in the worst cases, the floor erupts like a geyser, flooding the home.

How Stable are Texas Soils?

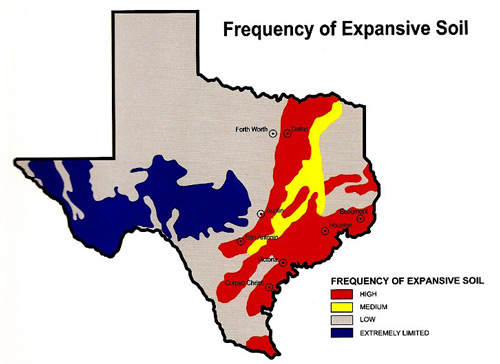

Texas has a wide variety of climatic and geological environments, which includes more than 1,300 varieties of soils in 21 Major Land Resource Areas. Dallas-area soils are notoriously expansive and unstable. This is especially true of the Central Texas corridor that runs from Houston and Austin northward through Dallas, as shown by this map from foundation company Tella Firma.

Texas has a wide variety of climatic and geological environments, which includes more than 1,300 varieties of soils in 21 Major Land Resource Areas. Dallas-area soils are notoriously expansive and unstable. This is especially true of the Central Texas corridor that runs from Houston and Austin northward through Dallas, as shown by this map from foundation company Tella Firma.

Dallas is in the Blackland Prairie, where soils are among the most expansive in the nation. These soils have a high percentage of a type that expands with spring rains and develops large cracks as it dries out and contracts during the hot, dry North Texas summers.

Fort Worth lies in the Grand Prairie region, which has an entirely different soil composition. While more stable than Dallas soils, Fort Worth-area also soils are prone to the drying and cracking that causes foundation-threatening soil shift.

Signs You May Have a Slab Leak

Amazingly enough, many people aren’t familiar with the term “slab leak” or variations, including “expandable soils,” “expansive clays,” “heavable soils,” or “shrink-swell soils.” It’s little wonder people fail to notice the signs of a slab leak if they’re not even aware of the problem.

In fairness, slow leaks can go years without being detected. Changes can be so incremental they go unnoticed. It pays to investigate if you notice any of these signs of slab leaks:

- Higher water bills without increased personal usage

- Sounds of running water when no taps are open

- Foundation develops a crack

- Discolored or damp floor coverings

- Warm or damp places on floors

- Bad smell from floors or walls

- Uneven growth in lawn or foundation plants

- Visible shift in the soil around the structure

If you have one or more of these symptoms at your home you should contact a licensed plumber immediately to get a professional opinion. Plumbers are equipped with acoustic, sonic, pressure, electromagnetic, and gas tracer detection tools to locate water leaks in plastic and metal plumbing lines. Plumbers also do visual inspections with fiber optic plumbers’ cameras they run through the plumbing lines.

Options for Slab Leak Repair

If you need slab leak repair you will have some decisions to make. Whether to repair it should not be one of those decisions, considering the risk of property damage can run into the tens of thousands of dollars or higher.

The age, materials, and condition of a home’s plumbing system will dictate whether the job calls for repairs or replacement of a section of plumbing or a complete re-piping of the plumbing system beneath a home.

The age, materials, and condition of a home’s plumbing system will dictate whether the job calls for repairs or replacement of a section of plumbing or a complete re-piping of the plumbing system beneath a home.

Your biggest decision will be regarding a company to do the work. With a project of the scope of a slab leak repair, you should get opinions and estimates from more than one company. Ask for references and check them out thoroughly.

A big part of your decision will be how much you trust the people vying for the work. Another will be the way they propose to do it. You will find most contractors have a preferred method. Ask them to show you how they have precisely located the leak so they won’t have to continue searching for it once the digging starts.

Our plumbers use three of the four most widely recommended methods to repair slab leaks, including pipe re-routing, tunneling, and, when necessary, breaking through the concrete slab from the top. We make our recommendation after carefully studying the job and any complicating factors.

Regardless of the method used, this is a job for a professional, licensed plumber. Here’s how they stack up.

1. Pipe Rerouting/Re-piping

Sometimes it makes sense to avoid digging altogether and reroute plumbing above ground. For example, if a short section of pipe is the problem and it can be worked around by installing new plumbing lines, rerouting may provide a quicker and less disruptive solution.

Sometimes it makes sense to avoid digging altogether and reroute plumbing above ground. For example, if a short section of pipe is the problem and it can be worked around by installing new plumbing lines, rerouting may provide a quicker and less disruptive solution.

In some cases, such as when a home’s plumbing lines are encased in concrete and cannot be reached without destroying the slab, it may be best to re-pipe the whole house. Water supply lines can be routed around the slab, instead of beneath it. The plumber will determine where new pipes can be installed, such as in walls, through the attic, closets, and other structures that may conceal and protect it. In some cases, a little creative woodworking can add a new feature, such as crown molding, to hide the pipes.

Water continues to run through the old plumbing while new lines are installed, so you don’t have to move out while the work is being done. Then, the old lines are shut off and the new ones are opened.

2. Break Through the Slab

The shortest distance to the source of the problem may be straight down through the concrete slab, but that also may be the most disruptive and most expensive. Because of this, we cut through the slab when other options are not available or are less attractive for some reason. There is no one size fits all solution.

Likewise, foundation building and repair companies caution that not all slabs are alike: they are engineered for the location, especially considering soil type and depth. Some slabs should not be cut into at all, and the head of one Dallas foundation repair company says “…breaking through structurally suspended flat slabs should be avoided…” although properly re-poured patches are secure.

Breaking through the slab has some serious disadvantages for homeowners. Foremost is that you have to live somewhere else while the work is being done – the water is shut off, the noise from jackhammers and saws is deafening, and the dust in the air requires you to cover everything.

Breaking through the slab has some serious disadvantages for homeowners. Foremost is that you have to live somewhere else while the work is being done – the water is shut off, the noise from jackhammers and saws is deafening, and the dust in the air requires you to cover everything.

In addition, the soil that is removed either is left in a big pile in your home while work proceeds or is taken out with wheelbarrows. The flooring in affected rooms usually must be replaced (it may be difficult or impossible to match some hardwoods or tiles, for example), and you will have added costs for lodging and meals. As should be apparent, breaking through a slab to repair a slab leak also can be quite expensive.

3. Tunneling Beneath the Slab

In our experience tunneling beneath the slab offers a number of benefits for homeowners:

In our experience tunneling beneath the slab offers a number of benefits for homeowners:

- you can stay in your home while work is in progress,

- the mess is kept outside of your home, and

- it’s often the least expensive choice.

Most homeowners prefer tunneling if they have expensive flooring. Some of the flooring, perhaps a room or more, would be destroyed by breaking through the slab from the top.

Some plumbers dig their own tunnels, others use engineers who do the digging and certify their work. Structural integrity is vital to a plumber working in a tunnel that can extend well beneath a house – we have worked in tunnels as long as 100 feet. Tunnels are dug about 3’ x 3’ to allow adequate working space.

Correctly replacing the dirt that was removed is essential. When the new plumbing has been installed and tested we refill the tunnel with the soil previously removed. We dampen the soil as we go and use metal tamps to pound it firmly back into place.

4. Trenchless Pipe Repair – Pipe Lining and Pipe Bursting

Pipe lining, or cured-in-place pipe (CIPP) has become a popular option for many homeowners because it involves no trenching and very little digging to gain access to the problem area. The concept is simple: broken water lines can be repaired by lining the inside of a broken pile with an epoxy coating that dries and hardens to form a new pipe.

Underground pipes that have become corroded, have holes, or cracks are the main candidates for this type of repair. First, a cutting tool removes debris and buildup, then the line is rinsed. A resin-coated liner is placed in the pipe along with an inflatable tube, Air pressure presses the liner against the inside of the pipe. It dries in a few hours, forming a new plastic pipe inside the damaged pipe.

As good as this sounds, the process is not foolproof. In fact, some contractors who do the work lack the confidence to provide a warranty. Problems develop when the epoxy does not adhere to the pipe wall properly, or when the coating is not evenly applied, as shown in this image provided by a company that specializes in re-piping apartment buildings. Uneven distribution constricts the pipe and pitting shows the liner is eroding, in this case, after two years.

Any subsequent leaks are more difficult to repair because no heat can be used. You may have no choice then but to re-pipe, which could have been done at the outset, and pay a second time to solve the same problem.

Any subsequent leaks are more difficult to repair because no heat can be used. You may have no choice then but to re-pipe, which could have been done at the outset, and pay a second time to solve the same problem.

Pipe bursting, also called pipe splitting, is sometimes used to replace badly damaged water lines. It also is a trenchless solution, but instead of lining the inside of the damaged water line with epoxy, a new pipe is inserted with a “bursting head” that is a little bigger than the diameter of the damaged pipe. It destroys the old pipe as it is pushed or pulled through.

Does Homeowners’ Insurance Cover Slab Leaks?

In a cruel addition of insult to injury, many homeowners find to their surprise that their homeowners’ insurance will be of little help paying for slab leak repair. Do not assume you are covered, ask. Insurance companies deal more in the sudden and catastrophic than gradual damage over time. They usually chalk up such gradual damage to poor maintenance, for which they are not liable.

If a pipe beneath the slab were to burst suddenly, your policy may provide some coverage. But that’s not how most slab leaks work. They may go years without being detected, slowly dripping away money and washing away soil. Seepage, or leakage, is usually provided by optional coverage that most people don’t purchase, mainly because they are unaware it exists.

If a pipe beneath the slab were to burst suddenly, your policy may provide some coverage. But that’s not how most slab leaks work. They may go years without being detected, slowly dripping away money and washing away soil. Seepage, or leakage, is usually provided by optional coverage that most people don’t purchase, mainly because they are unaware it exists.

Those who have leakage coverage in most cases will have coverage for foundation and slab repairs, but not the expense of the plumbing work. Their consolation is that the foundation or slab work usually is the biggest part of the cost. If you have this coverage it is essential to know if there is a sub-limit on the total amount covered.

A sub-limit is a kind of a “gotcha” that limits the insurance company’s liability for specific types of coverage, which usually includes seepage. Do not assume it is the full amount of your property coverage.

An Ounce of Prevention…

Now that you know your home is likely to have been built on unstable, expansive soil; that you may have a slab leak of which you may be entirely unaware for years, and that your insurance may not cover the damage, prevention does seem worthwhile, doesn’t it? Here are some things you can do.

Keep the soil around your house moist year around. We can go for weeks on end with no rain, which makes this step essential. There should be no gap between the foundation and the soil. If you don’t have an irrigation system use a garden hose a couple of times each week or use a soaker hose. This article provides a good overview of how to use a soaker hose for foundation irrigation. Don’t overdo it. About ¼ inch each time is sufficient. Target the water to land about 10-15 inches from the house.

Keep the soil around your house moist year around. We can go for weeks on end with no rain, which makes this step essential. There should be no gap between the foundation and the soil. If you don’t have an irrigation system use a garden hose a couple of times each week or use a soaker hose. This article provides a good overview of how to use a soaker hose for foundation irrigation. Don’t overdo it. About ¼ inch each time is sufficient. Target the water to land about 10-15 inches from the house.- Be careful what you put down the drain. Chemical drain cleaners and other household cleaners are harsh and can damage plumbing lines. Fats, oils, and grease can clog drains, as can pieces of bone and fruit pits. This article lists 16 things that should never go down a drain or toilet.

- Test the pH of your water. Water that is too acidic can have the same effect as harsh chemicals – and remember, it’s in your water lines all the time. A plumber will be glad to do this for you if you’d rather not do it yourself.

- Check your home’s water pressure. Most home plumbing systems are built to maintain 40-60 PSI. Higher pressure puts additional stress on pipes and joints that can result in leaks at weak spots and pipe connections.

- Get annual plumbing inspections. This is something most people never do, but an annual plumbing inspection is as important as annual tune-ups on your air conditioning and heating systems. Any leak repaired is likely to save enough on your water bill to pay the cost of the inspection. Some companies, such as billyGO, off this as part of a comprehensive maintenance package.

CONCLUSION

Slab leaks happen when the plumbing lines beneath a home fail for any reason. They may go undetected for years, slowing dripping away, eroding the soil, and weakening the slab and foundation.

Slab leaks may be caused by faulty installation, weakened water lines, or chemical reactions of metal plumbing lines to metals in the earth. In the Dallas/Fort Worth metro area, the biggest cause is expansive soil that expands when wet and contracts when dry. Shifting soil weakens and cracks plumbing lines causing leaks beneath the concrete slab.

Repair costs can be in the tens of thousands of dollars, and many homeowners’ insurance policies provide little or no coverage. Knowing the warning signs that you may have a slab leak, your options for repairing it and ways to prevent slab leaks is essential information for homeowners. If you think you might have a slab leak contact us today.

We have plumbers experienced with locating slab leaks standing by in Dallas-Fort Worth.